- No products in the cart.

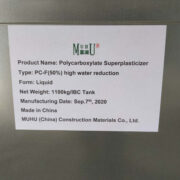

Concrete Admixture – Polycarboxylate Superplasticizer Ether of High Water Reduction PC-F

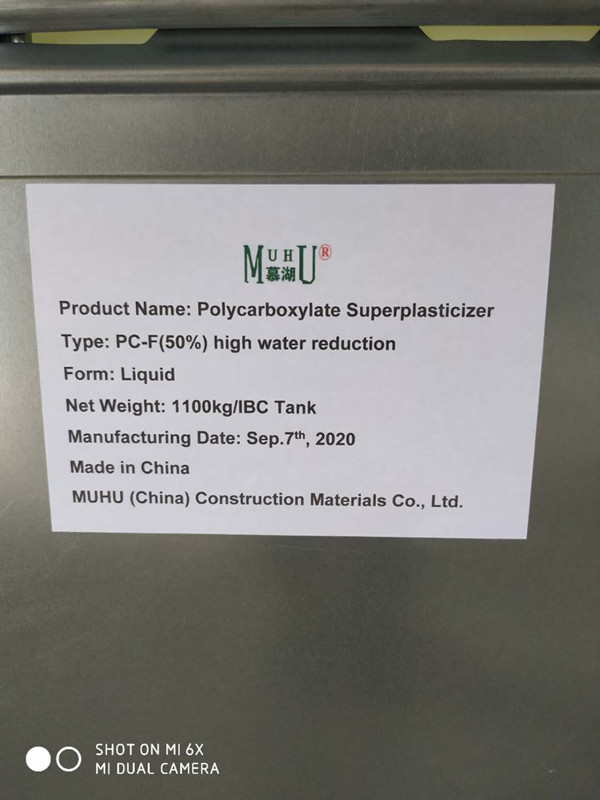

Product Name: Polycarboxylate Superplasticizer of High Water Reduction (PC-F)

Type: PC-F(primary liquid)

Package: 230 kg/drum , 1100 kg / IBC Tank

Polycarboxylate Superplasticizer (PC-F) is a liquid that uses to improve the superb water-reducing performance in the application of ready mixed and precast concrete industries.

Polycarboxylate Superplasticizer Ether of High-Water Reduction

PC-F High Water Reducing Rate (Concrete Additives for Strength)

Description

PC-F is a ready-to-use liquid superplasticizer that immensely improves the overall water-reducing performance when compared with superplasticizers based on existing polycarboxylic systems.

PC-F Polycarboxylate Superplasticizer for high water reduction has been primarily developed for applications in the ready-mixed and precast concrete industries where the highest durability and performance are required.

Standards Compliance

PC-F Polycarboxylate Superplasticizer for high water reducing complies with all requirements of the following standards: ASTM C 494, Type E & F. BS EN 934-2.

Typical Properties

|

Items |

Specification |

|

Visual Appearance |

Light Yellow Liquid |

|

Solid Content (%) |

50.0±2.0 |

|

Density (23℃) (kg/m3) |

1.13±0.02 |

|

Chloride Content (%) |

≤0 |

|

Na2SO4 Content (%) |

≤4.0 |

|

Na2O+0.658K2O (%) |

≤5.0 |

|

Solubility |

Completely soluble |

Usage

1) PC-F for high water reducing is suitable for long-distance transported pumping concrete, high fluidity concrete, self-leveling concrete, plain concrete, free vibration self-compacting concrete, and high strength concrete, etc.

2) PC-F for high water reducing can be widely used in hydraulic projects, electric power, ports, railways, bridges, roads, and other various projects.

Advantages

1) PC-F water reduction is up to 35% and its concrete slump is not lost in one hour.

2) PC-F has good storage stability, no precipitation or lamination at low temperature.

3) PC-F could be blended into 10% solution with water, which can be directly used as pumping aid agent.

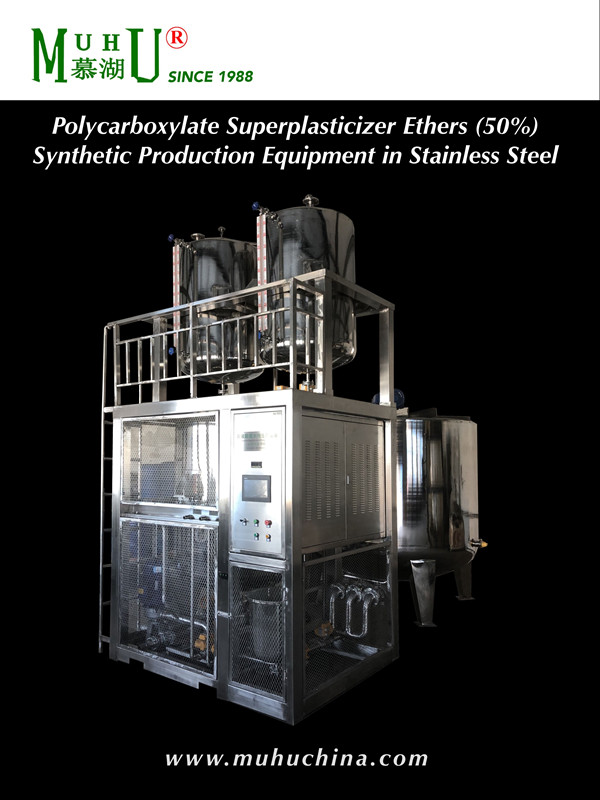

4) Production clean degree is high: Due to formaldehyde, industrial naphthalene, acetone or other flammable, and toxic chemicals being not used in production process, it meets cleaning production standard. This new production technology is a fully automated process without heat production.

5) Safety: This product is non-toxic, non-radioactive or non-flammable. There is no harmful material for steel and aggregate. There is no formaldehyde or other harmful aromatic residues. It meets the requirements of indoor and outdoor environment.

Dosage

■ The optimum dosage of PC-F to meet specific requirements should always be determined by trials using the materials and conditions that will be experienced in use.

Dosage range: C × 0.3% —- 1.0%

Recommended dosage: C × 0.5% (calculated according to PC-F). Before using or when replacing cement, determine the optimal dosage through concrete testing.

Packaging, Storage and Transport

■ This product is a liquid packaged with plastic drum, 230 kg/drum, or 1000 Liter / IBC tank. Available in bulk according to customer’s requirements.

■ This product is non-toxic or non-flammable. Keep in dry place and away from direct sunlight.

■ PC-F polycarboxylate superplasticizer has a minimum shelf life of 12 months provided it is stored or under cover.

Stainless Steel Polycarboxylate Superplasticizer Ether Synthetic Production Line.