- No products in the cart.

Keywords: concrete admixture equipment, admixtures equipment used in ready mix concrete, ready mix concrete admixtures equipment, Precast concrete admixtures equipment.

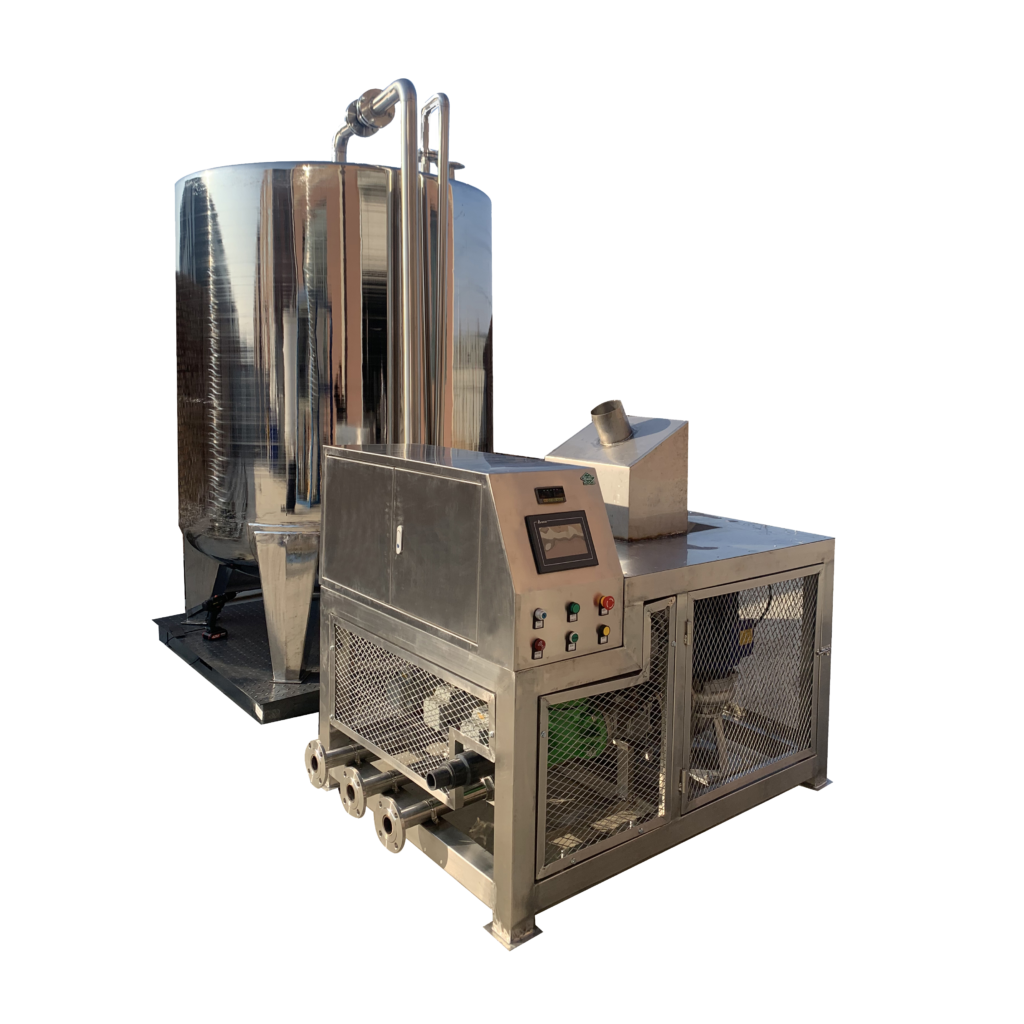

Automatically Controlled Mobile Blending Equipment for Concrete Admixtures

(MH-BM-02A)

Ideal for Blending Admixtures Plants

■ Overview

With the improvement of people’s living conditions and the progress of our society, field workers have stronger expectations for better production settings, especially for less pollution and lower labor intensity. Construction contractors have more and more stringent requirements for project quality. This requires that the admixture performance is better, the production process is more environmentally friendly, and the quality is more assured. Production equipment must be developed and improvement.

MUHU develops a new generation of automatically controlled mobile blending / compounding equipment for concrete admixtures. This equipment is multi- purpose admixture compounding equipment. It can be used in concrete production enterprises and admixture blending plants.

Watch this video for detailed information of the production equipment and technology know-how transfer of heatless production line for concrete admixtures.

■ Features

Ergonomic engineering design

1. Automatic control allows one button press to complete the whole production. In the entire process, only one worker is needed.

2. This equipment has changed the traditional top-feeding mode production. The operator stands on the ground floor to complete the feeding task safely and easily.

3. This equipment has a dust collector, which results in a cleaner environment and protects the workers’ health.

4. This equipment can blend polycarboxylate based admixtures, naphthalene based admixtures, or other powders and liquids.

Unique high-pressure spray dispersion equipment

The unique hybrid technology and the high-pressure spray dispersion technology are adopted to effectively solve the long mixing time of compulsory mixer. High-pressure spray equipment can make materials dispersed evenly. Compared with traditional mixing, the efficiency is greatly improved.

Removable and modular-based

The installation and disassembly is fast and easy, which makes it convenient to produce in different locations. Thus, it greatly reduces the cost of shipping materials to different station.

Multiple protection prompts, more secure and reliable production

1. Buzzer prompt: When worker manually input the powder materials or when production is completed to allow discharge, different sound is used to remind.

2. LCD display, formula edit/save/ selection function: Through the relevant text prompts on LCD screen, the used can easily edit, save and select the formula, without reading the operation manual.

3. Recovering from emergency and power failure: The electronic control system not only allow to edit/ store concrete admixtures blending formula, but also to save and track each step in the production process. In the event of emergency (urgency or power outage), the program can be stopped by pressing a key. After the status is recovered, one key pressed can continue the production. There is no quality accident.

4. Operation security setting: in order to ensure the confidentiality of production formula and the safe operation of equipment, different passwords can be set for each operator and formula editor.

High output with complete mix

The system can blend 2 tons/5 tons/10 tons of admixtures per batch, which takes 20min. Accordingly, 4 to 20 tons of admixtures can be produced per hour. This output rate makes it possible for just-in-time production strategy.

■ Seeking Partnerships

MUHU company has been committed to the production, research, development and sales of concrete admixtures for more than 30 years and has provided professional technical service support worldwide for the admixtures industry. MUHU company has won hundreds of national patents, including:

1. the patented product technology of polycarboxylate superplasticizer in 2003;

2.the patented technology of polycarboxylate production equipment in 2013;

3.the patented technology of polycarboxylate production in laboratory in 2019.

In order to enable more customers to share MUHU patented equipment and product services and meet the needs of local production, both parties hereby agree to sign the following agreement.

■ Equipment Provided:

1. One set PC Synthesis unit and lab-scale equipment of Stainless Steel Equipment.

2. One set PC blending units and lab-scale equipment of Stainless Steel Equipment.

■ Policy:

We can provide our partners in each city with the equipment they need.

1. The partner shall use MUHU patented equipment, that is a fully automated, intelligent, PLC operating system.

2. The partner needs to pay the equipment deposit by full telegraphic transfer before using MUHU equipment.

3.The partner shall have a one-year trial period of the equipment and MUHU will provide professional support services for any technical problems;

4. After MUHU financial department gets 100% T/T in advance deposit, the partner has the right to use the equipment but cannot transfer nor sell the equipment to a third party without the consent of MUHU;

5. The partner will need a workshop area of: 500 square meters, length: 20 meters, width: 12-15 meters, height: 6.0 meters.

6. Initial transformer application: 110KW, initial power consumption: 50KW.

7.Initial water consumption: 2 tons/hour, 20 tons of water storage tank per day.

8. The technical royalty fee for the PC Synthesis and PC blending units should be covered by partners.

MUHU will always be customer-centric and continuously focused on being your reliable partner in the admixture industry.

■ Equipment Images

■ Contact information

Joice Ma, Director

MUHU Construction Chemicals

Beijing, China

Tel: 86-10-69687750

fax: 86-10-69687750

Mobile: 86-13911293982

UAE Mobile: 00971-50-739-6168

www.muhuchina.com

Email: export@muhuchem.com

Skype: export@muhuchem.com

WhatsApp or WeChat: 0086 139 112 93982