- No products in the cart.

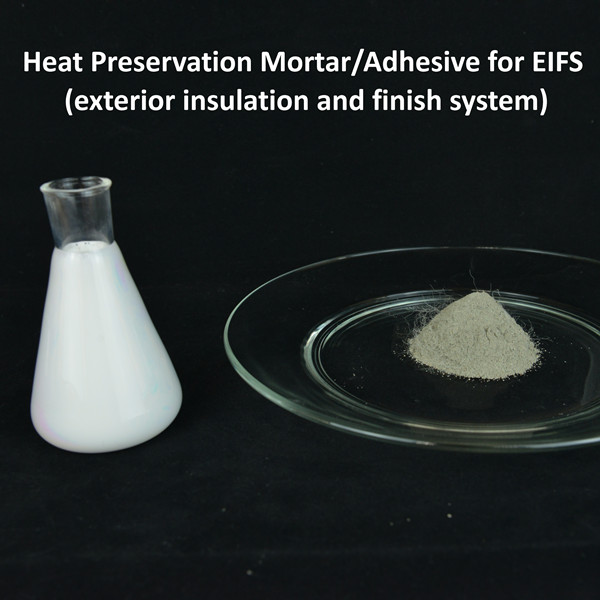

Heat Preservation Mortar

Product Name: Heat Preservation Mortar

Type: Heat Preservation Mortar

Package: 50 kg / bag

Heat preservation mortar is a revolutionary system formulated by cementitious material(cement, sand, fly ash)superfine active material and additives for application in exterior wall. It perfectly combines the flexibility of high polymer materials with durability of inorganic materials. It can glue to alkali-resistance gridding cloth. It has excellent adhesion with mortar and alkali-resistant gridding cloth, introducing a protection layer. It reduces hydration heat at early stage and mortar shrinkage. It improves workability, ultimate strength and impermeability. Water spraying and special curing is not necessary after application of it.

Features and Benefits

- Strong bonding strength, good crack resistance, impact-resistance, anti-aging and water proof ability.

- Double edged with flexibility and durability, it has a defense system to both cold and heat variations of exterior temperature. It improves pore structure and crack resistance of mortar by compensating shrinkage.

- Good waterproof and breathable performance. There is also water retention property.

- Non-toxic, odorless and no pollution.

- Wall with this system can be decorated by using coatings, surface tiles or curtain walls.

Test Data Sheet

According to the national construction industry standard JG149 – 2003 expanded polystyrene board plaster exterior insulation system.”

| No. | Items | Criteria | Actual Results | |

| 1 | Cohesive strength, MPa

(with expansion polyphenyl panel) |

Normal condition | Destruction on expanded polystyrene panel interface ≥ 0.10 | 0.18 |

| Moisture resistance | Destruction on expanded polystyrene panel interface ≥ 0.10 | 0.18 | ||

| Anti-freezing/thawing | Destruction on expanded polystyrene panel interface ≥ 0.10 | 0.13 | ||

| 2 | Maximum operational time, h | 1.5 ~ 4.0 | 2 | |

| 3 | compressive strength / flexural strength | ≤ 3.0 | 2.1 | |

Application

- It’s used in grid cloth top coating of exterior wall heat preservation system, repairing of cracks in base layer and concrete defects as well.

- It’s used in top coating of heat preservation panel, interior & exterior wall, air-entrained concrete wall, hollow bricks wall and roof.

Uses

- Fully stir the mix of adhesive, heat preservation mortar and blending water. 10 minutes after agitation stops, it’s ready for use.

- The process from agitation to use-up shouldn’t take more than 2 hours.

- Do not add water randomly during use.

- Prohibit the construction during rainy day and when wind is more than 6 level;

- Anti-freezing type of heat preservation mortar is preferable when daily average temperature is below 5℃.

Recommended Consumption

- Recommended consumption upon 1 m2 is 1-1.5kg. One ton can cover 1000-800 m2 based on wall flatness.

- Coating thickness is 3-5 mm at consumption rate of 1-1.5kg/m2.

Package, Storage & Handling

- It’s packed in 50kg/bag.

- It should be stored in a dry and well ventilated ware house. Avoid damp contamination.

- Its shelf life is 12 months.