- No products in the cart.

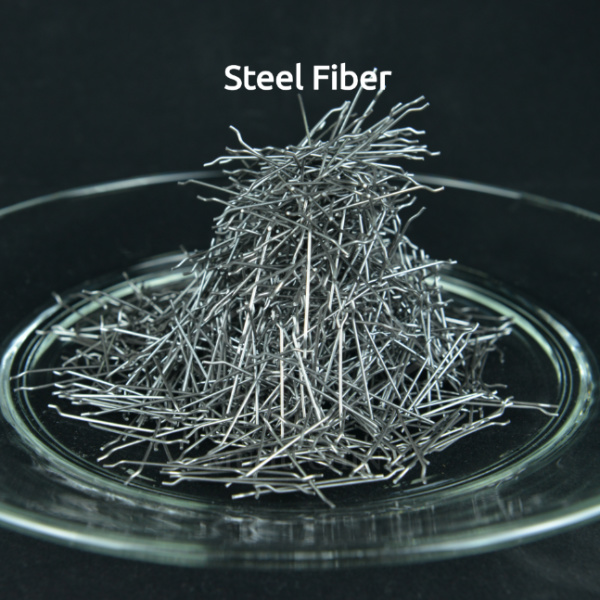

Steel Fiber

Product Name: Steel Fiber

Type:

Package: 15 kg/bag

Application

It’s widely used in road pavement, water reservoir, nuclear power station, airport apron and runway, the fundament of high-rise buildings, underground garage, mine tunnels, air-raid shelter, bullet shelter, bridge, culvert, stilling basin, heavy base, wharves and warehouse floor that load above 30 tons, port, marine engineering, rocket launch site, concrete structures that require explosion-resistance and wave-resistance.. It ‘s used to meet the requirement of tensile strength, compressive strength, bending strength, seismic resistance, shear strength, anti-cracking ability, anti-fatigue etc in important area.

Features & Advantages

1.Compared with reference concrete, the cross-sectional thickness of steel fiber reinforced concrete reduces by 50%.

2.The use of materials such as cement, stone and sand can be saved by 50%.

3.Spread steel fiber in the mixtures in different layers will save the consumption by 45%.

4.The distance among shrinkage joints will be improved by 11-13 times (It’s possible to extend it and arrive at 50-60m)

5.Steel fiber reinforced concrete has 80% explosion resistance more than reference concrete. Owing to this feature, it’s used in important areas, such as covert projects and launch basis of bullet invulnerable rocket.

Test Parameters

| Items | Improvement over reference concrete |

| Impact Strength | 40-60% times |

| Explosion Resistance | 160-180% times |

| Anti-crack strength | 200% |

| Tensile Strength | 200% |

| Shear Strength | 4-6 times |

| Twist Resistance | 200% |

| Bending Strength | 200% |

| Compressive Strength | 25% |

| Anti-fatigue strength | 100 times |

| Anti-wearing Ability | 30% |

| Elongation | 200% |

| Moving Friction | 15% |

| Anti-seepage | 80% |

| Hot Resistance | remarkable |

| Cold Resistance | remarkable |