- No products in the cart.

Keywords: Laboratory Synthesis Equipment, Plant production test, Synthesis of Polycarboxylate Superplasticizer, Lab Scale equipment, Ultra high performance concrete additives Equipment, PCE superplasticizer concrete admixture, polycarboxylate ether superplasticizer

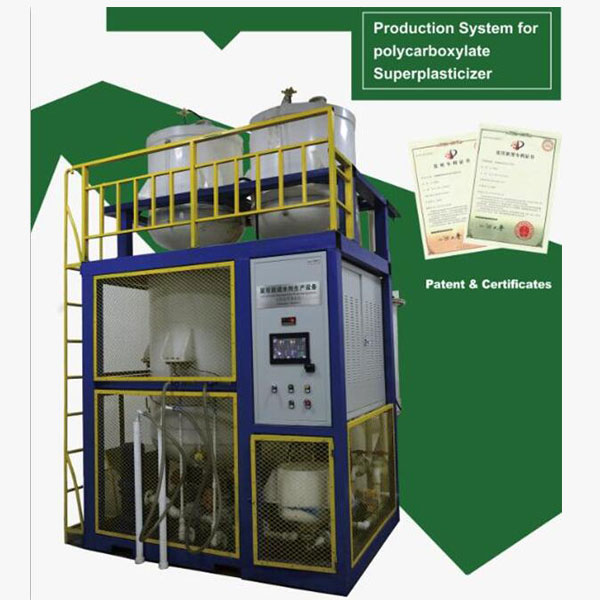

Lab Scale Production System

for Polycarboxylate Ether(PCE) Superplasticizer

MH-PCT-01M(5L)

■ Overview:

For manufacturers of polycarboxylate superplasticizers, they often encounter the problem of changing the production formula or raw materials supplies that affect the stability of product quality.

Based on our production experience, MUHU company developed a set of Lab Scale Systems to produce Polycarboxylate Ether (PCE) Superplasticizer. With this equipment, lab technicians can easily test their new production formulas and improve the production processes of PCE Superplasticizer. Similarly, production workers can use this equipment to perform pilot or test production in case the raw material gets changed prior to batch production to get stable and high-quality finished products.

Watch this video for detailed information of lab scale production system for PCE Superplasticizers.

■ Products To be Produced

The equipment can be used to produce high water reducing type PC-F (polycarboxylate superplasticizer), high slump retention type PC-G (polycarboxylate superplasticizer) and special set retarders for PCE superplasticizer type PC-R (50%) at ambient temperatures. No heating system is needed.

■ Scope of Use

- Laboratory synthesis

- Test production in plant

■ Features

- Intelligent Production

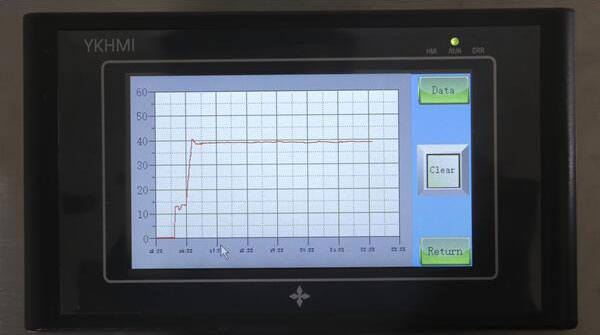

PLC control, touch screen operation, displaying material dripping time and real-time reaction temperature chart;

- Unique Design using Stainless Steel

- Special material feeding design for large quantities of powder products

Special material feeding design for large quantity of powder products, making it easy and fast to input TPEG/HPEG monomer material;

- Accurate Measurement

The measuring system can meet both needs of laboratory for micro material and regular scaling for typical materials such as large monomer and water. Quantity measurement ranges from 0.01g to 5000.00g.

- Precise Automatic Dripping Control

Step motor operating the peristaltic pump is used for material dripping. The pump is controlled by PLC with self-memorizing and correction function which satisfies the precise drip addition for different materials.

- Precise Automatic Temperature Control

Accurate control of material initial temperature and constant temperature, the accuracy is 0.1 C;

- Large Production Range

Any quantity from 2 Liter to 5 Liter can be produced normally.

- Integrated Power Source

As the result of high integration, only one power cord is used for several equipment and devices.

- Convenient and fast discharging

Convenient and fast discharging through the valve at the bottom.

■ Price & Delivery Time

Door to door price: 5,000 USD. You will receive the equipment and raw materials within 10 working days after you make the full payment.

■ Technical Support & Services

We can show you how to use this equipment to produce polycarboxylate ether superplasticizer. If you are satisfied with the result, you can carry out normal production with our machine for large-scale production.

■ Partner Representative

We can help partners in each city with our equipment.

■ Contact information

Joice Ma, Director

MUHU Construction Chemicals

Beijing, China

Tel: 86-10-69687750

fax: 86-10-69687750

Mobile: 86-13911293982

www.muhuchina.com

Email: export@muhuchem.com

Skype: export@muhuchem.com

WhatsApp or WeChat: 0086 139 112 93982